ULTRAPLATE

UTE "ULTRAPLATE" is intended for automatic ultrasonic testing (UST) of plate and strip in metallurgical works (online construction of the test unit) as well as on the certain area of testing (offline construction of the test unit).

Источник: http://service-joomla.ru/plagini/item/19-allvideos.html

GALLERY

-

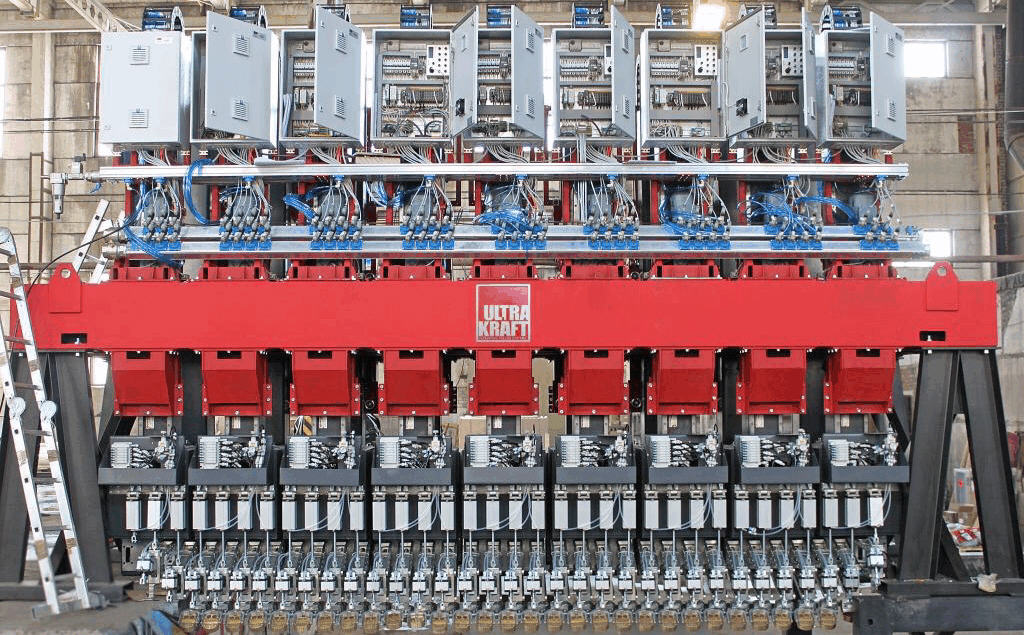

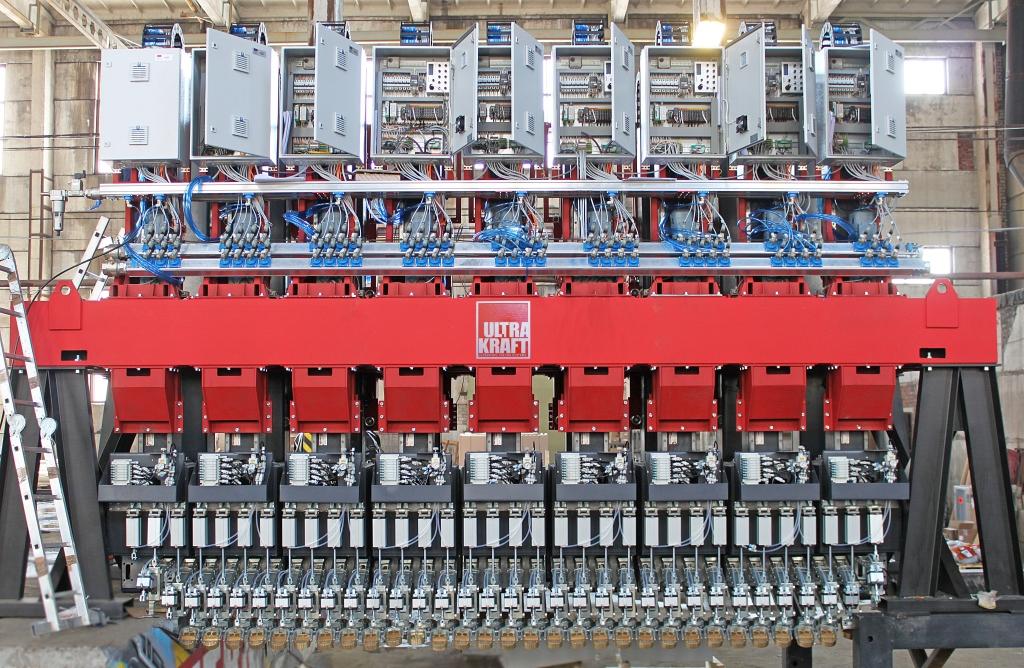

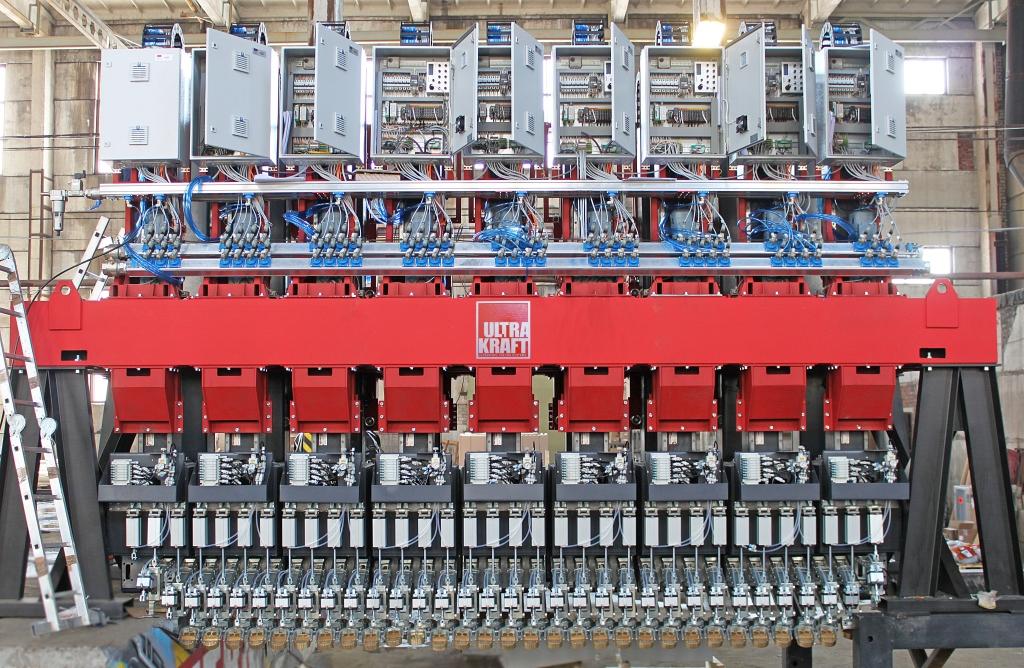

Overview of the test unit during the controlled assembly and cold tests before a shipment to the Customer

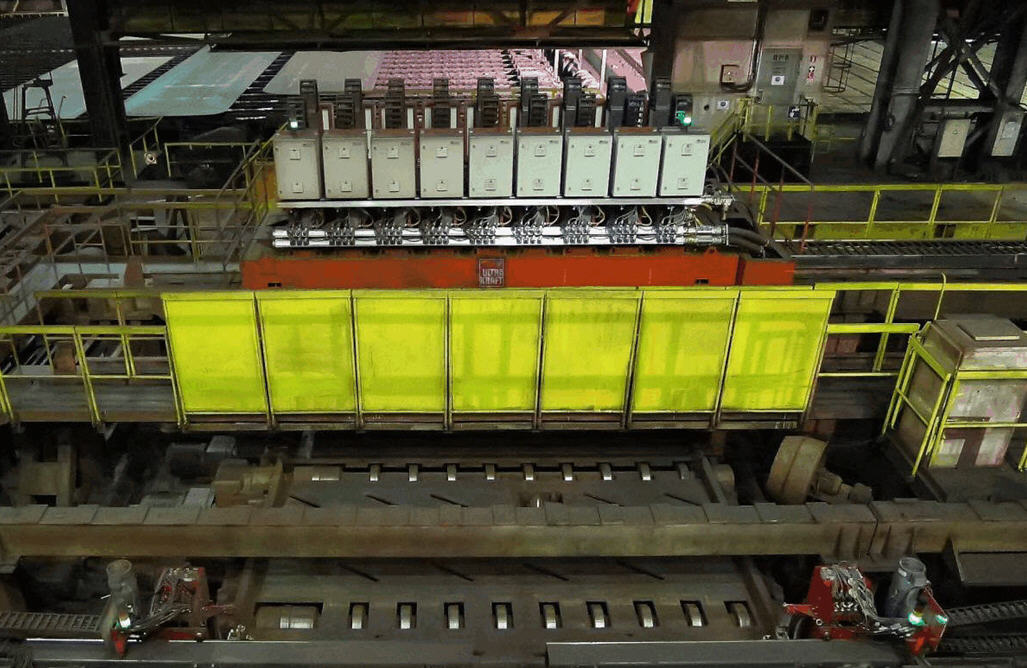

Overview of the test unit (the unit is in line)

Overview of the test unit (the unit is the service area)

Overview of the test unit (the unit is in line)

Overview of the test unit of the base metal testing and test units of edge zones

-

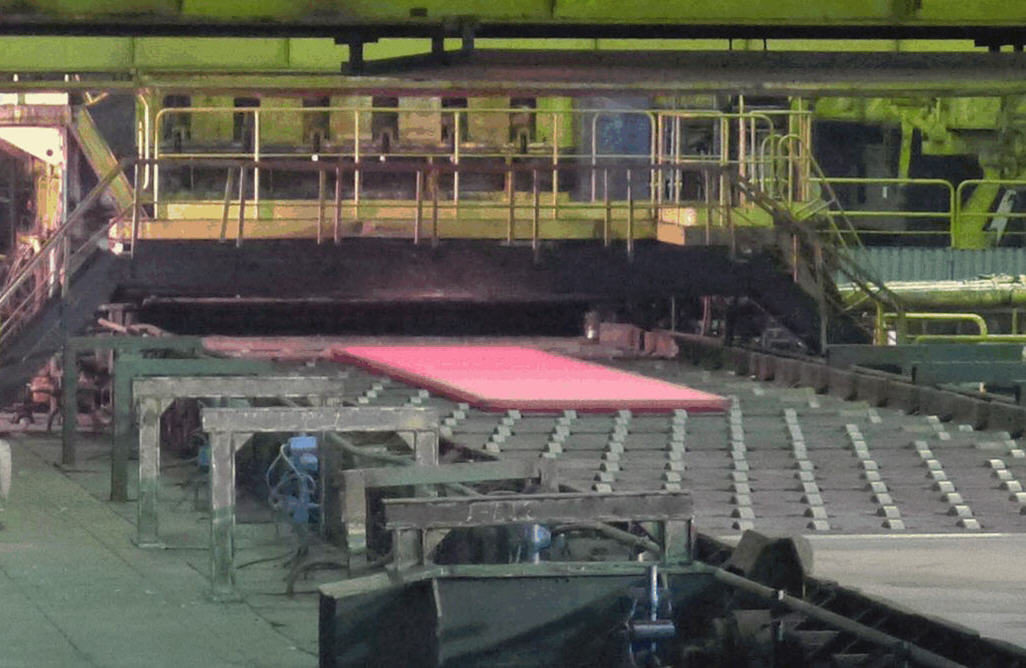

US-Testing of hot Plate

Overview of the test units of edge zones

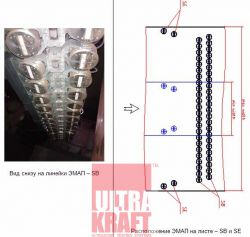

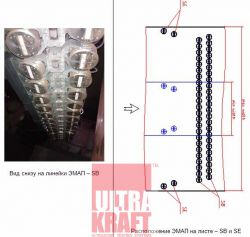

EMATs on plate

View on the lines of the EMAT

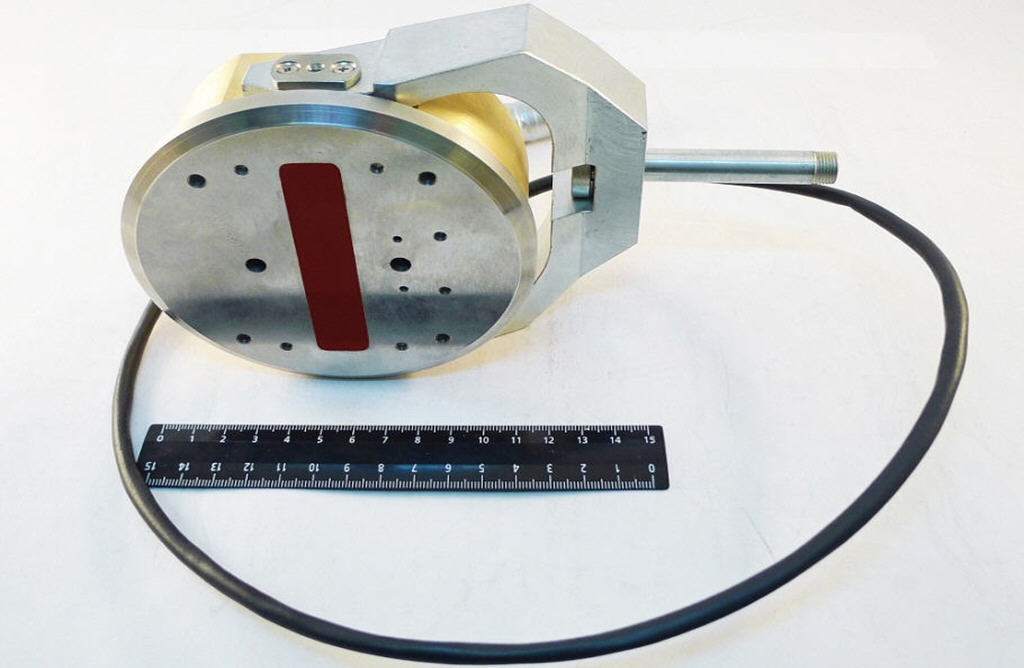

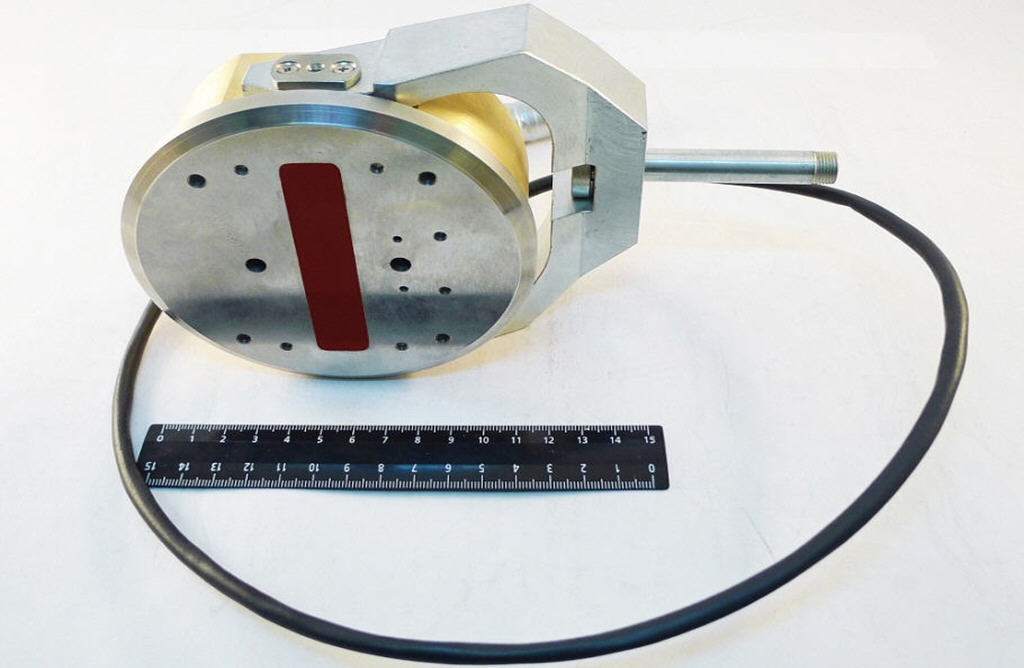

Electromagnetic aquistic transducer (EMAT)

-

NDT Electronics Unit

MAIN ADVANTAGES OF EQUIPMENT

- Ultrasonic testing by using of the electromagnetic acoustic transducer (EMAT) without contact liquid and the necessity of its regenerating and recycling;

- Surface temperature of the testing plate is up to 720 Celsius degree;

- Testing of the plate and strip with the high curvature;

- High testing reliability of the plate and strip with dirty surface;

- Testing speed during transportation of the plate and d strip is up to 2.0 m/s;

- High sensitivity of internal flaw (lamination) is equivalet to FBH2;

- Detection of surface and subsurface flaws such as cracks, slivers, rolling marks, etc with the depth of 0.2 mm and size of more than 1 mm.

MAIN CHARACTERISTICS OF THE EQUIPMENT

| | Plate | Strip |

|---|

| Edge condition |

Cut off and unedged |

- |

| Width |

1000 – 5500 mm |

>300 mm |

| Thickness |

5 – 75 mm

(>75 optionally)

|

> 1,2 mm |

| Temperature |

up to 720 Celsius degree |

| Transportation speed |

up to 2,0 m/s |

up to 20 m/s |

| Thickness accuracy |

± 0,05 mm |

| Sensitivity to surface flaws |

depth 0,2 mm no more than 1 mm |

| Sensitivity to lamination |

FBH2 |

|

Efficiency (it depends on standard size of plate and strip)

|

дup to 4.5 mln tonne per year |

up to 1 mil tonne per year |

QUALITY ASSESSMENT

Quality assessment is carried out according to the following standards GOST 22727, SEL 072, ISO 12094, API 5L, ASTM 435, ASTM 578, DNV-OS-F101, EN10160, JIS0901, JIS0801, ISO10893, ISO3183 and analogs to them.

TRACKING SYSTEM OF THE PLATE EDGE POSITION AND ITS POSITION ON TRANSFER LINE

Realization by using of non-contact laser scanner with the high-temperature construction.

EMAT

|

|

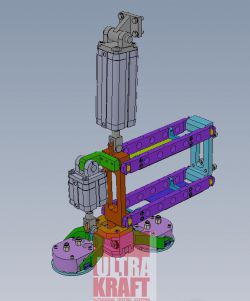

The number of the testing channels in the EMAT-block varies from 4 to 16 and depends on the requirements and test conditions.

The lower part of EMAT has the shape of a circle. Such a shape is optimal for effective positioning of EMAT regarding the plate surface during scanning.

|

|

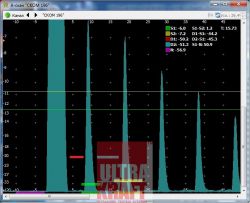

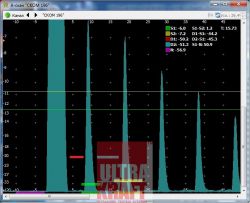

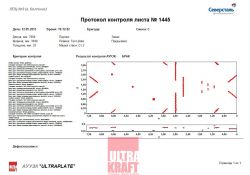

A-scan of plate testing at 620 Celsius degree.

|

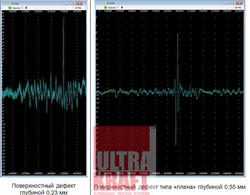

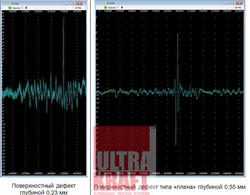

SURFACE FLAW DETECTION

|

A-scan of a surface flaw |

|

Test result protocol of the plate for surface flaws. The protocol shows the result of plate scanning having different flaws such as blister and fold with the depth of 0.2 - 0.6 mm. |

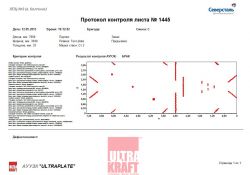

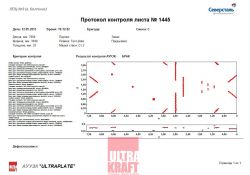

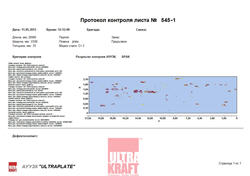

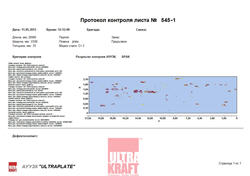

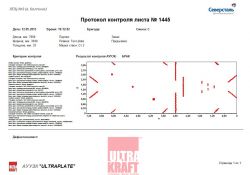

TEST PROTOCOLS

| Protocol of basic matal testing. |

Information about the location of the plate thickness flaws (depth of the flaws) may be included in the protocol at the request of the Buyer. |

|

|

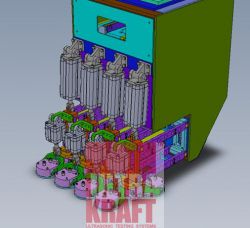

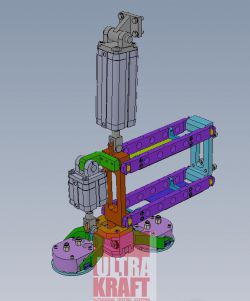

MULTICHANNEL PROBES

|

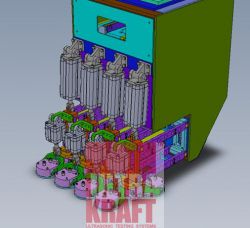

Equipment is structurally divided into two units:

- The body plate testing (strip) unit - SB - two lines of EMAT are staggered;

- Two test units for edge zones - SE - provide the autoposition of the EMATs relative to the plate edge (strip) in case of the plate displacement during the testing or curvature of the plate edges (strip).

The number of the unit probes SB depends on the maximum possible plate width (or strip width).

|

|

EMAT-blocks are grouped into sections. The number of sections depends on maximum possible plate width. Each section contains 4 universal lift/down mechanisms of EMAT-blocks. Each mechanism has two EMAT-blocks staggered relative to each other, and as result they provide overlapping of the scan lines. |

|

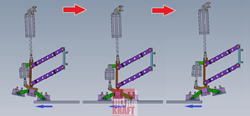

Overview of the section grop with lift/down mechanism of the SB-lines.

EMAT-line.

|

|

Overview of the universal lift/down mechanism of EMAT is ready-assembled.

This universal lift/down mechanism of EMAT is a part of the intellectual property of Ultrakraft, ZAO and is protected by a patent of the Russian Federation.

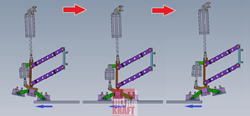

Direction of the plate moving is shown with the blue arrows. The red arrows show three states of operating of the lift/down mechanism of EMAT.

|

NDT ELECTRONICS

|

Equipment is mounted in the tight construction with protection class IP 67 according to the international standard IEC 60529 (DIN 40050, GOST 14254-96). Besides it provides the full electromagnetic compatibility with the Buyer's equipment.

Electronics unit can contain up to 32 straight channels (without commutation).

Electronics unit contains up to 32 channels. The new electronic unit does not have a cooling liquid and consumes 8 times less power than the equipment of competing firms, so it provides the efficiency and reliability of non-destructive testing.

|