NDT OF TUBE

ULTRATUBE

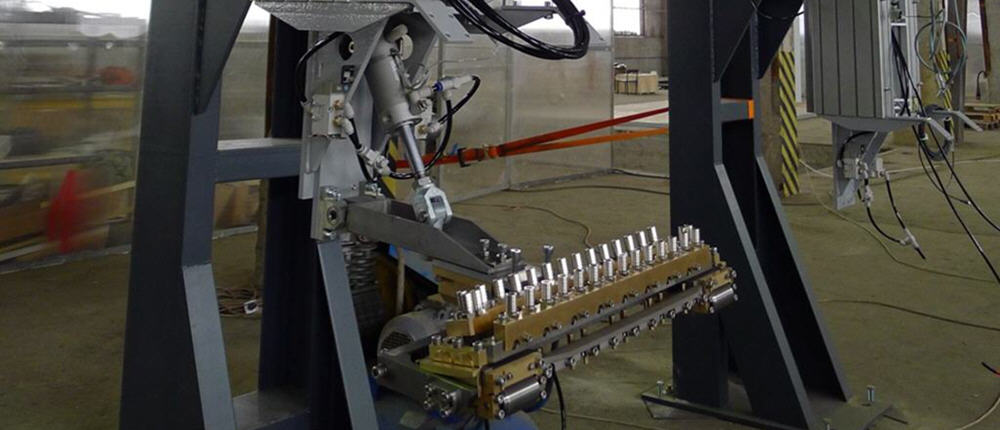

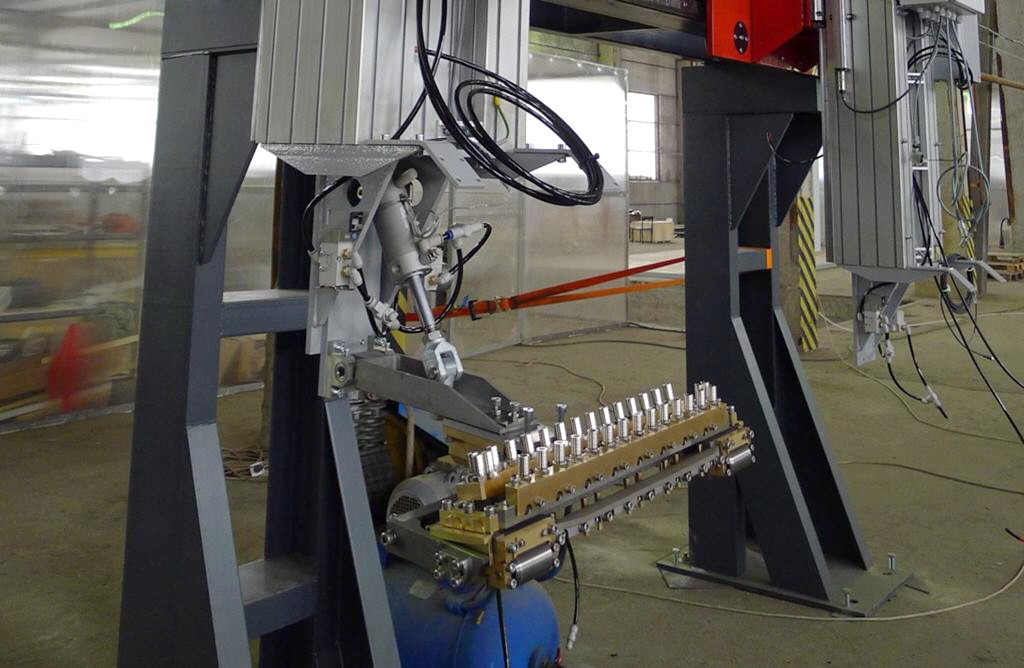

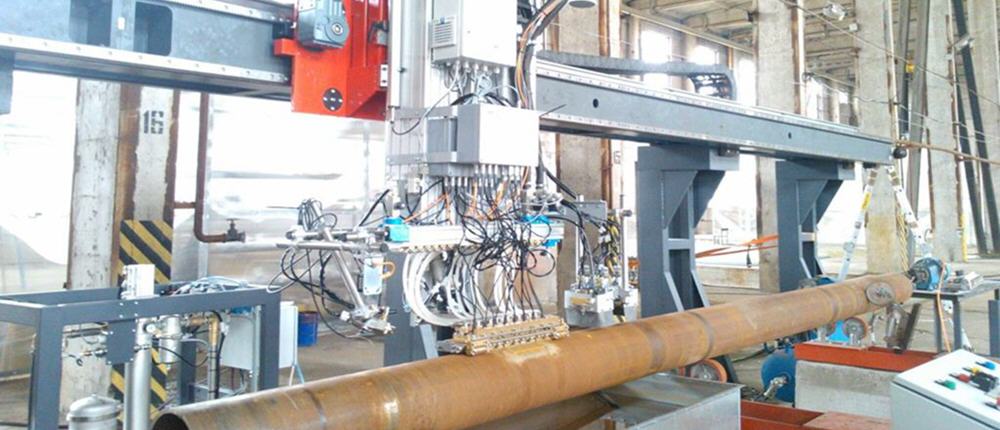

UTE “ULTRATUBE” is intended for automatic ultrasonic testing (UST) of weld, heat affected zone pipe ends areas as well as pipe body of electric-welded and seamless pipes of the small and mean diameter.

Источник: http://service-joomla.ru/plagini/item/19-allvideos.html

GALLERY

MAIN ADVANTAGES OF EQUIPMENT

Testing of the pipe body (around the perimeter) for the the longitudinal, transverse flaws, laminations, as well as ultrasonic thickness measurements and flaws of inclined orientation.

- Testing of the pipe ends areas for the the longitudinal, transverse flaws, laminations, as well as ultrasonic thickness measurements and flaws of inclined orientation;

- The Equipment provides the testing by using of conventional piezoelectric probes as well as by using of Phased arrays.

- Independent testing of the weld andpipr ends areas for longitudinal, transverse flaws, laminations, sa well as ultrasonic thickness measurements and flaws of inclined orientation;

- Automatic calibration of the Equipment in line, with automatic loading and unloading of calibration block.

MAIN CHARACTERISTICS OF THE EQUIPMENT

|

Small and mean diameter pipes, seamless and electric-welded pipe , welded with ERW and LBM | |

|---|---|

| Diameter | 50 – 630 mm |

| Length | up to 18500 mm |

|

Efficiency |

up to 150 pipe/h |

|

Sensitivity to the longitudinal, transverse and inclined flaws |

The notch depth of 3% of the wall thickness and length of 9 mm (Notch N3) |

| Testing sensitivity to internal flaws | FBH 3 |

QUALITY ASSESSMENT

Quolity assessment is carried out according to the following standards API 5L, API 5CT, GOST R 52079, GOST14782-86, GOST R 53366, ISO 11960, ISO 3183, DNV-OS-F101, Shell Technical Specification, as well as according to the specification of Exxon Mobil.

EQUIPMENT CALIBRATION

With the Equipment you can automatically carry out the regular calibration according to the calibration block.

Two types of calibration are available:

according to the small-size calibration block – in this case the calibration can be automatically carried out before and after the pipe testing with creation of the calibration results. If the calibration is unsuccessful, the equipment will automatically stop the pipe testing and give warning of necessity to adjustment.

according to the full-size of the pipe with artificial flaws in the processing line.

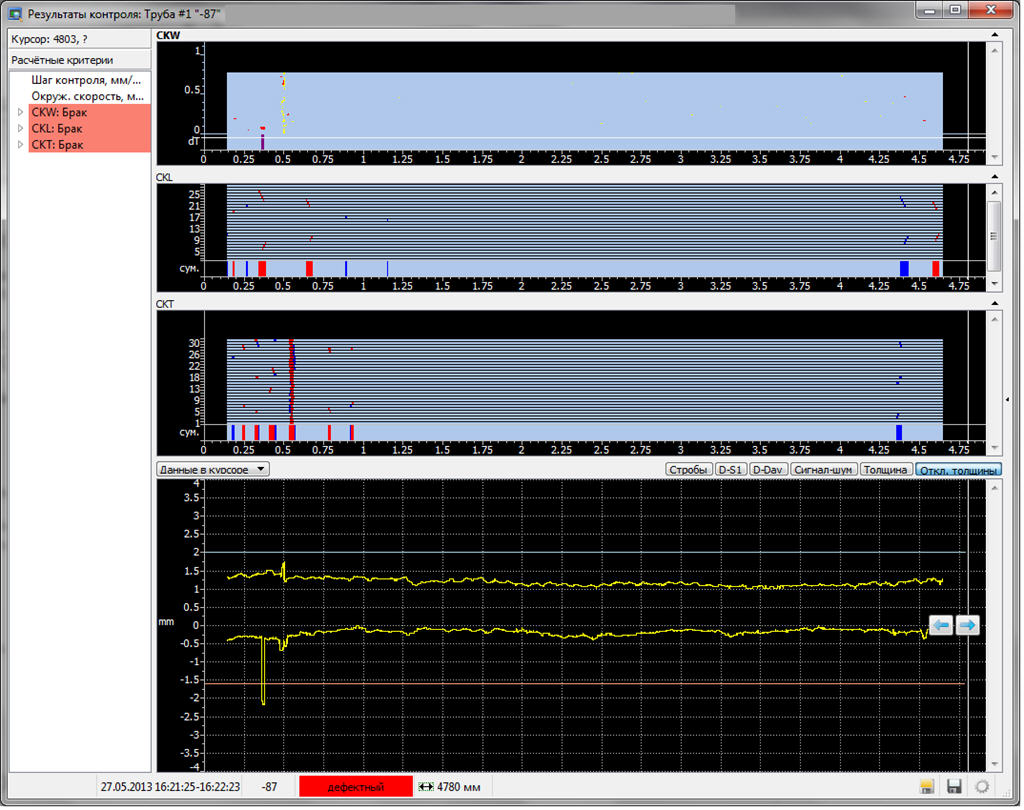

OVERVIEW OF B-SCAN

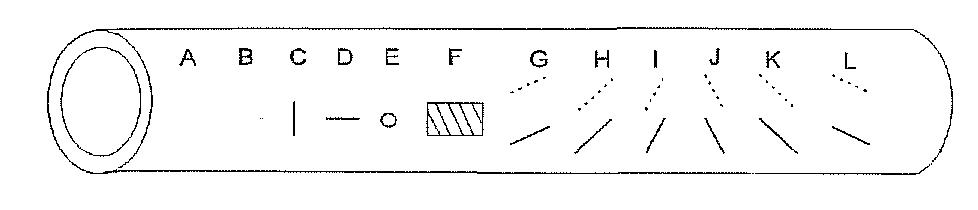

REFERENCE BLOCK FOR EQUIPMENT CALIBRATION

(according to the requirements of EXXON MOBIL)

|

Flaw |

Type |

Surface |

Length (inch) |

Width (inch) |

Depth (% from normal wallthickness) |

|---|---|---|---|---|---|

| A | Longitudinal | OD (outside surface) | 0.5-1.0 | .006 - .020 | 3% |

| B | Longitudinal | OD | 0.5-1.0 | .006 - .020 | 3% |

|

C |

Longitudinal | ID (inside surface) | 0.5-1.0 | .006 - .020 | 3% |

|

D |

Longitudinal | ID | 0.5-1.0 | .006 - .020 | 3% |

| E | Flat-bottom hole (FBH) | OD or ID | 1/8" diameter (optionally 1/16" diameter) |

1/8" diameter( optionally 1/16" diameter) | Depth, installed according to EMQSP-2.5 |

| F | Reduced wall | OD or lD | 0.5 | 0.5 | 10% - 12,5% |

| G | 22° to the left | ID and OD | 0.5-1.0 | .006 - .020 | 5% |

| H | 45° to the left | ID and OD | 0.5-1.0 | .006 - .020 | 5% |

| I | 67° to the left | ID and OD | 0.5-1.0 | .006 - .020 | 5% |

| J | 67° to the right | ID and OD | 0.5-1.0 | .006 - .020 | 5% |

| K | 45° to the right | ID and OD | 0.5-1.0 | .006 - .020 | 5% |

| L | 22° to the right | ID and OD | 0.5-1.0 | .006 - .020 | 5% |

TYPES OF EQUIPMENT EMBODIMENT

- Bridge-type - the pipe rotates during testing on the reversible rollers, the measuring unit moves along the pipe scanning its perimeter. The longitudinal (progressive) and transverse loading/unloading of the pipe in the testing zone.

SHOW 3-D EQUIPMENT OF BRIDGE-TYPE

- Statiionary type - the pipe moves revolute translational through the testing zone. In this case a fixed measuring unit scans the pipe during its transportation through the testing zone.