NDT OF SLAB

ULTRASLAB

UTE "ULTRASLAB" is intended for automatic ultrasonic testing (UST) of continuous casting (slabs) in cold or hot condition (up to 1000 Celcius degree).

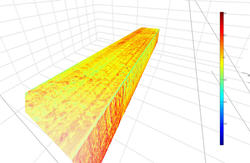

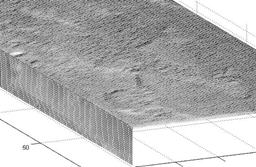

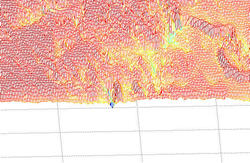

GALLERY

MAIN ADVANTAGES OF EQUIPMENT

- Ultrasonic testing by using of the electromagnetic acoustic transducer (EMAT);

- Automatic detection of surface flaws on both sides of the continuous casting (slab);

- Automatic detection of internal flaws in the continuous casting (slab);

- Automatic detection of cracks in slab edge area;

- Additional scanning of the slab surface with the laser triangulation 2D-scanners of high temperature trim.

MAIN CHARACTERISTICS OF THE EQUIPMENT

| Slab width | up to 2400 mm |

| Slab thickness | up to 320 mm |

| Slab temperature | up to 950 Celsius degree |

| Types of typical flaws to be detecting |

|

CONSTRUCTION OF TEST UNIT

is similar to the construction of the test unit «ULTRAPLATE» («online» or «offline» constructions).

is additionally equipped with a system of continuous laser scanning of the slab surface with the 2D-scanners to detect local anomalies of the slab surface.

provides 3D Laser-scanning of the slab surface for detection of the local surface flaws.

|

|

|

|

LOCATION OF THE EQUIPMENT

There are two variants of location:

- at a special area for non-destructive testing (for example, at slab yard);

- "in line", after a continuous casting machine, it means immediately after cutting of the continuous casting for slabs. The slab temperature is up to 950 degrees Celsius.